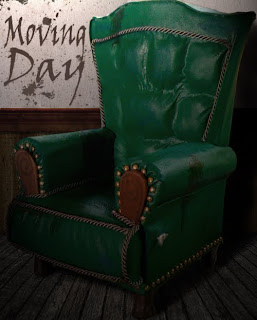

Hello everyone! We're still moving onwards and upwards. Man, this whole "create an entire world and animate it one frame at a time" is extremely fun! I become overly ecstatic whenever I see something new that the guys are working on even if it's a small, seemingly insignificant object that will probably only get about 0.5 seconds of actual screen time. It doesn't matter, they put their all into it! The level of talent and detail that these guys have is just amazing so I dedicate this blog post to everyone working on the props for the film and will show you all a few of the props these guys have hammered out.

The first here is the broom. The broom is a prop that plays a significant role in the film so it had to be detailed. What I like about this prop is the fact that the creator (Steve) took the time to actually modify a real brush as opposed to creating the entire thing in clay. My personal taste as a director agrees with the use of realism even in an animated medium. Great job, Steve!

This magician's hat and variations of magic wands were created by Jared. What I love about this prop is that it captures a rustic, cartoonish spirit but still remains grounded in reality (if that makes sense). It has life in it and hopefully that comes across in my poorly taken camera phone photo.

Love, love, LOVE this piece. It is technically considered a prop piece which falls under Brian's jurisdiction but I don't care! I love it! The picture doesn't do it justice as I only took a picture of one side of the tree. But what I love about it is the very clear and distinct immediate mood or feeling you retrieve from it. That's hard to pull off effectively! Props to Brian!

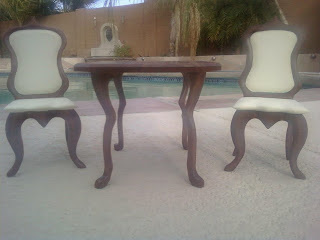

Wait... How big are those chairs and table? That's right, these props are at a 2" = 1' scale. Look at the detail! Look at the structure, design and architecture of these pieces! Amazing work! Steve has proved his talent once again! Below I've added just a quick photoshop I've created to give you a further look as to how the piece would end up as these props are technically still in the process of being made.

These guys are really adding an amazing value to this film. As a director, I cannot wait to see this film in it's completion and share their talent with everyone else. We are starting production soon and we are looking into ways to provide you all with a more intimate involvement with the creation of this film so stay tuned Moving Day watchers!

Read more!

Again lining up and mapping out our shots. Nick (Producer) and Duane (Animator)

Again lining up and mapping out our shots. Nick (Producer) and Duane (Animator)

Dad? Just some concept art of Chris' dad. He may be on the site but not in the actual animation. More to come on that!

Dad? Just some concept art of Chris' dad. He may be on the site but not in the actual animation. More to come on that!